1 semiconductor industry

Zinc oxide is by far the hardest one in Group II-VI semiconductor materials, which means that zinc oxide can prevent the proliferation of other II-VI materials that are defective in their application to light emitting devices;

Zinc oxide as a UV detector has a very low dark current, the maximum response wavelength up to 350 nm;

Zinc oxide materials are transparent in the 0.4-2 μm wavelength range and have piezoelectric, optoelectronic and other effects, thus providing electrical, optical and acoustic devices such as light sources, detectors, modulators, optical waveguides, filters, and related circuitry Such as the possibility of monolithic integration. So has aroused the interest of many researchers.

2 rubber, plastic industry

Nanometer zinc oxide is the rubber industry’s most effective active agent and vulcanization accelerator. Nanometer zinc oxide powder has large specific surface area, small particles, good dispersibility, loose and porous, good fluidity and other physical and chemical characteristics. Therefore, it has good affinity with rubber, easy dispersion when melting, low heat generation of rubber compound, Broken deformation is small, good elasticity, improve the material properties and physical properties of the process for the manufacture of high-speed wear-resistant rubber products. Such as aircraft tires, limousine radial tires, with anti-aging, anti-friction ignition, long life and other advantages, substantially improve the rubber finish, mechanical strength, temperature and aging resistance, especially wear resistance.

In addition, zinc oxide as a rubber vulcanization system complete with additives, the higher the amount of filling, usually about 5 parts, due to large proportion of zinc oxide, a large amount of filling, the density of the rubber compound is very large, the Product life and energy consumption are negative, and the use of nano-zinc oxide, the amount of grade zinc oxide is only 30% -50%, reducing the production costs of enterprises, and in the tensile properties, heat, aging, etc. Are far better than ordinary zinc oxide.

Zinc oxide for the plastics industry, with the polymer material composite, with a strong bond between the substrate material, not only can improve the rigidity and hardness of the material, but also enhance the toughening effect. Due to the nano-ZnO shielding UV properties, the application of these materials can also improve the UV resistance.

3 ceramic industry

The extremely small particle size, large specific surface area and high chemical property of nano zinc oxide can significantly reduce the sintering density of the material, save energy, densify and homogenize the composition and structure of the ceramic material, improve the performance of the ceramic material, Improve the reliability of its use, can control the composition and structure of the material from the structural level of the nano-material, which is conducive to giving full play to the potential performance of the ceramic material,

In addition, since the size of the ceramic material determines the microstructure and macroscopic properties of the ceramic material, if the powder particles are uniformly packed, the sintering shrinkage and the crystal grains grow uniformly, the smaller the particles, the smaller the defects, The higher the strength of the prepared material, the more likely it is that some large particles do not have the unique properties.

4 cosmetics industry

In order to avoid excessive ultraviolet radiation on human skin damage, people have developed a variety of sunscreen skin care products. Early use of sunscreen skin care products more salicylic acid, amino acid, cinnamic acid, benzophenone and other organic UV inhibitors. The advantages of organic UV anti-UV sunscreen is high efficiency, but the sunscreen does not last long and stimulate the shortcomings of the skin.

In recent years, we have developed nano-zinc oxide, titanium dioxide, kaolin, talc and other inorganic anti-UV agent. Nano-zinc oxide UV absorption ability, UVA and UVB have a good shielding effect.

As an inorganic anti-UV agent, nano zinc oxide is non-toxic, odorless, non-irritating, non-decomposing, non-degenerating and has good thermal stability. Its safety is approved by the U.S. Food and Drug Administration and can be used as a sunscreen, makeup foundation and Lipstick and other raw materials.

5 catalyst industry

Due to its small size, large specific surface area and different bonding state between the surface and the particles, the nano-sized zinc oxide increases the contact surface and improves the catalytic efficiency. It is the first choice for chemical production enterprises to prepare chemical catalysts and desulfurization agents. Compared with ordinary oxidation Compared with zinc, zinc oxide has a larger specific surface area, and the number of atoms on the surface increases. As a result, more active catalytic sites are exposed, and the resulting catalysts are more active.

Nanometer zinc oxide used as desulfurizer is petroleum refining, ammonia, methanol, organic synthesis and chemical fiber and other industrial raw materials gas (oil) purifier, in addition can also be used as briquette, coking and flue gas desulfurization process.

Nano-ZnO for the removal of SO2 gas also has a good effect. Nano zinc oxide desulfurizer with wide temperature range, high purification, long life B sulfur C high capacity and other characteristics, the desulfurization reaction, the gas content of hydrogen sulfide can reach below 23%.

6 other fields

With the deepening of people’s understanding of the performance of nano zinc oxide, the scope of the application of nano-zinc oxide is constantly expanding, for example, the use of nano-zinc oxide in traditional coating technology can further improve the protective coating, making it UV-resistant Irradiation, resistance to atmospheric damage and degradation, discoloration and other functions;

The nano zinc oxide to a certain percentage added to the propionic acid coating, the system can be made with excellent antibacterial antibacterial nano-coating. Nanometer zinc oxide is very sensitive to the external environment (such as temperature, light, moisture, etc.), small changes in the external environment will quickly lead to changes in their surface ionic and electronic motion, which immediately led to significant changes in resistance. Using the sensitive nature of nano-ZnO, high-sensitivity gas alarms and hygrometers are produced.

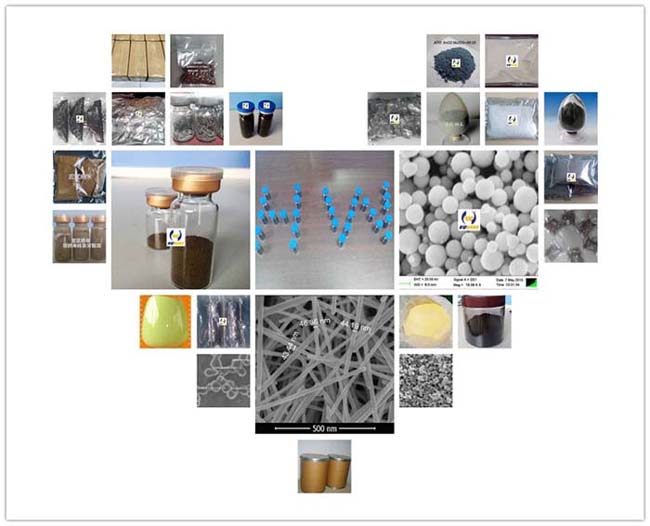

To make a summary, nano-ZnO has become a new type of high-performance fine inorganic powder products for the 21st century. At present, researchers at home and abroad have developed various methods to prepare various forms of nano-zinc oxide products. Studies on nano-ZnO have been made A great progress has been made, but there are still some shortcomings in the preparation methods such as high cost, complex process and difficulty in industrialization.

In addition, the research on the structure and the application properties of nano ZnO has not been further studied. Therefore, the follow-up research focuses on the development of a simple, efficient and easy-to-manufacture method. The effect of the material structure on its optical, electrical, magnetic and acoustic performances is further studied. Applied technology research, with a view to give full play to the nano-size effect of materials in end products such as high-energy solar cells, photoreceivers, gas sensors and biosensors. With the improvement of nanometer zinc oxide production process, nanometer oxide industry application will enter a stage of rapid development.

Related reading:antibacterial agent zinc oxide nano zinc oxide powders